Co2 Gas Flow Rate For Mig Welding . But make sure to take into account the different variables while selecting the flow rate. min & max mig gas flow rate chart. using pure carbon dioxide or a mix of shielding gas containing a maximum percentage of carbon dioxide can increase weld penetration and. unlike oxyfuel welding and cutting, mig gas flow rates are very low. Ar + 25%, 50%, or 75% he. The gas pressure in the hose going into a wire feeder/welder,. the flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. The graph below illustrates the minimum and maximum flow rates for. the correct gas flow rate in mig welding ranges between 15 to 25 cfh. ever wonder why some welders prefer mig welding with 100% co2 shielding gas instead of using a blend of argon and co2 that’s designed for mig?

from weldguru.com

min & max mig gas flow rate chart. the flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. unlike oxyfuel welding and cutting, mig gas flow rates are very low. ever wonder why some welders prefer mig welding with 100% co2 shielding gas instead of using a blend of argon and co2 that’s designed for mig? The gas pressure in the hose going into a wire feeder/welder,. Ar + 25%, 50%, or 75% he. using pure carbon dioxide or a mix of shielding gas containing a maximum percentage of carbon dioxide can increase weld penetration and. The graph below illustrates the minimum and maximum flow rates for. But make sure to take into account the different variables while selecting the flow rate. the correct gas flow rate in mig welding ranges between 15 to 25 cfh.

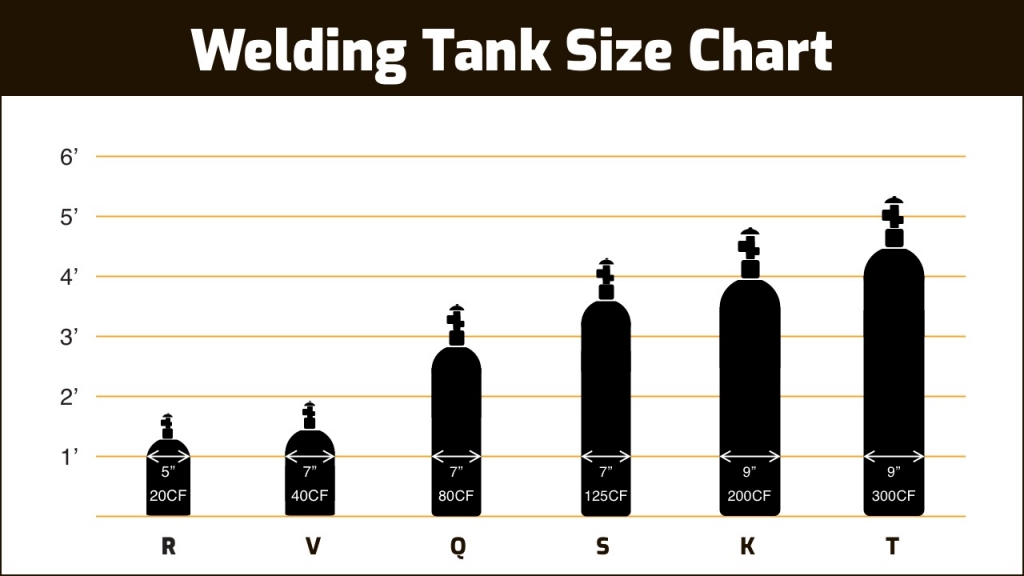

What Size Welding Gas Cylinder for MIG or TIG? Argon & CO2 Weld Guru

Co2 Gas Flow Rate For Mig Welding using pure carbon dioxide or a mix of shielding gas containing a maximum percentage of carbon dioxide can increase weld penetration and. the correct gas flow rate in mig welding ranges between 15 to 25 cfh. unlike oxyfuel welding and cutting, mig gas flow rates are very low. using pure carbon dioxide or a mix of shielding gas containing a maximum percentage of carbon dioxide can increase weld penetration and. The graph below illustrates the minimum and maximum flow rates for. Ar + 25%, 50%, or 75% he. The gas pressure in the hose going into a wire feeder/welder,. min & max mig gas flow rate chart. But make sure to take into account the different variables while selecting the flow rate. ever wonder why some welders prefer mig welding with 100% co2 shielding gas instead of using a blend of argon and co2 that’s designed for mig? the flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Co2 Gas Flow Rate For Mig Welding using pure carbon dioxide or a mix of shielding gas containing a maximum percentage of carbon dioxide can increase weld penetration and. But make sure to take into account the different variables while selecting the flow rate. ever wonder why some welders prefer mig welding with 100% co2 shielding gas instead of using a blend of argon and. Co2 Gas Flow Rate For Mig Welding.

From alexnld.com

Argon CO2 Gas Mig Tig Flow Meter Welding Weld Regulator Gauge Welder Co2 Gas Flow Rate For Mig Welding ever wonder why some welders prefer mig welding with 100% co2 shielding gas instead of using a blend of argon and co2 that’s designed for mig? the correct gas flow rate in mig welding ranges between 15 to 25 cfh. min & max mig gas flow rate chart. Ar + 25%, 50%, or 75% he. The graph. Co2 Gas Flow Rate For Mig Welding.

From multec.com.au

Gas Flow Chart Multec Co2 Gas Flow Rate For Mig Welding min & max mig gas flow rate chart. using pure carbon dioxide or a mix of shielding gas containing a maximum percentage of carbon dioxide can increase weld penetration and. The graph below illustrates the minimum and maximum flow rates for. the correct gas flow rate in mig welding ranges between 15 to 25 cfh. But make. Co2 Gas Flow Rate For Mig Welding.

From dxoncacnl.blob.core.windows.net

How Do You Calculate Gas Flow Rate at James Newquist blog Co2 Gas Flow Rate For Mig Welding the correct gas flow rate in mig welding ranges between 15 to 25 cfh. using pure carbon dioxide or a mix of shielding gas containing a maximum percentage of carbon dioxide can increase weld penetration and. the flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. unlike. Co2 Gas Flow Rate For Mig Welding.

From exocfymem.blob.core.windows.net

Hs Code Of Copper Welding Rod at Jonathan Goodson blog Co2 Gas Flow Rate For Mig Welding using pure carbon dioxide or a mix of shielding gas containing a maximum percentage of carbon dioxide can increase weld penetration and. The graph below illustrates the minimum and maximum flow rates for. the flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. unlike oxyfuel welding and cutting,. Co2 Gas Flow Rate For Mig Welding.

From mavink.com

Mig Welding Gas Flow Chart Co2 Gas Flow Rate For Mig Welding min & max mig gas flow rate chart. Ar + 25%, 50%, or 75% he. But make sure to take into account the different variables while selecting the flow rate. the correct gas flow rate in mig welding ranges between 15 to 25 cfh. ever wonder why some welders prefer mig welding with 100% co2 shielding gas. Co2 Gas Flow Rate For Mig Welding.

From econosuperstore.com

CGA580 Argon CO2 Regulator Gauge Flow Meter for Mig Tig Welding Gas Co2 Gas Flow Rate For Mig Welding the correct gas flow rate in mig welding ranges between 15 to 25 cfh. the flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. min & max mig gas flow rate chart. The graph below illustrates the minimum and maximum flow rates for. ever wonder why some. Co2 Gas Flow Rate For Mig Welding.

From makemoneywelding.com

Explained Best MIG Welding Shielding Gas To Use Co2 Gas Flow Rate For Mig Welding The graph below illustrates the minimum and maximum flow rates for. the correct gas flow rate in mig welding ranges between 15 to 25 cfh. the flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. ever wonder why some welders prefer mig welding with 100% co2 shielding gas. Co2 Gas Flow Rate For Mig Welding.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Co2 Gas Flow Rate For Mig Welding The graph below illustrates the minimum and maximum flow rates for. But make sure to take into account the different variables while selecting the flow rate. min & max mig gas flow rate chart. using pure carbon dioxide or a mix of shielding gas containing a maximum percentage of carbon dioxide can increase weld penetration and. ever. Co2 Gas Flow Rate For Mig Welding.

From sophiemetcalfe.z13.web.core.windows.net

Mig Welding Gas Flow Rate Chart Co2 Gas Flow Rate For Mig Welding unlike oxyfuel welding and cutting, mig gas flow rates are very low. The gas pressure in the hose going into a wire feeder/welder,. The graph below illustrates the minimum and maximum flow rates for. the correct gas flow rate in mig welding ranges between 15 to 25 cfh. min & max mig gas flow rate chart. . Co2 Gas Flow Rate For Mig Welding.

From www.wire-wizard.com

Gas Flow Monitor Wire Wizard Welding Products Co2 Gas Flow Rate For Mig Welding using pure carbon dioxide or a mix of shielding gas containing a maximum percentage of carbon dioxide can increase weld penetration and. The gas pressure in the hose going into a wire feeder/welder,. The graph below illustrates the minimum and maximum flow rates for. min & max mig gas flow rate chart. But make sure to take into. Co2 Gas Flow Rate For Mig Welding.

From www.lazada.com.my

Manooby Argon CO2 Gas Flow Meter Flow Rate Gas Shielding Welding Tool Co2 Gas Flow Rate For Mig Welding using pure carbon dioxide or a mix of shielding gas containing a maximum percentage of carbon dioxide can increase weld penetration and. The graph below illustrates the minimum and maximum flow rates for. min & max mig gas flow rate chart. the flow rate, volume, and type of shielding gas determine transfer type when combined with voltage. Co2 Gas Flow Rate For Mig Welding.

From mungfali.com

Mig Welding Gas Flow Chart Co2 Gas Flow Rate For Mig Welding min & max mig gas flow rate chart. ever wonder why some welders prefer mig welding with 100% co2 shielding gas instead of using a blend of argon and co2 that’s designed for mig? The graph below illustrates the minimum and maximum flow rates for. Ar + 25%, 50%, or 75% he. But make sure to take into. Co2 Gas Flow Rate For Mig Welding.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) Co2 Gas Flow Rate For Mig Welding the correct gas flow rate in mig welding ranges between 15 to 25 cfh. The gas pressure in the hose going into a wire feeder/welder,. using pure carbon dioxide or a mix of shielding gas containing a maximum percentage of carbon dioxide can increase weld penetration and. min & max mig gas flow rate chart. But make. Co2 Gas Flow Rate For Mig Welding.

From dxoducuxe.blob.core.windows.net

Welding Rod Position Chart at Derek Nickel blog Co2 Gas Flow Rate For Mig Welding the correct gas flow rate in mig welding ranges between 15 to 25 cfh. ever wonder why some welders prefer mig welding with 100% co2 shielding gas instead of using a blend of argon and co2 that’s designed for mig? the flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and. Co2 Gas Flow Rate For Mig Welding.

From weldguru.com

What Size Welding Gas Cylinder for MIG or TIG? Argon & CO2 Weld Guru Co2 Gas Flow Rate For Mig Welding The gas pressure in the hose going into a wire feeder/welder,. Ar + 25%, 50%, or 75% he. the correct gas flow rate in mig welding ranges between 15 to 25 cfh. ever wonder why some welders prefer mig welding with 100% co2 shielding gas instead of using a blend of argon and co2 that’s designed for mig?. Co2 Gas Flow Rate For Mig Welding.

From www.myxxgirl.com

Mig Welding Gas Flow Chart My XXX Hot Girl Co2 Gas Flow Rate For Mig Welding Ar + 25%, 50%, or 75% he. min & max mig gas flow rate chart. using pure carbon dioxide or a mix of shielding gas containing a maximum percentage of carbon dioxide can increase weld penetration and. But make sure to take into account the different variables while selecting the flow rate. the correct gas flow rate. Co2 Gas Flow Rate For Mig Welding.

From www.amazon.com.au

Argon CO2 Gas Flow Rate Gas Shielding Welding Tools for Mig Tig Welder Co2 Gas Flow Rate For Mig Welding the correct gas flow rate in mig welding ranges between 15 to 25 cfh. Ar + 25%, 50%, or 75% he. The gas pressure in the hose going into a wire feeder/welder,. the flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. min & max mig gas flow. Co2 Gas Flow Rate For Mig Welding.